Why Hotel Engineering?

- Hotel is dependent on sophisticated engineering equipment's.

- Examples: Air conditioning system, Ventilation, Water treatment plant, Sewage treatment plant, Sensors, Detectors, Fire fighting system and a lot more.

- As a Hospitality professional you need to have basic knowledge of these equipment's.

Importance of the Maintenance Department

- Keeping engineering facilities in optimal operating conditions is vital for the business of a hotel.

- Non – availability of a facility reduces the revenue and loss of future business potential

- The maintenance department aims at keeping all the engineering facilities in the best operating condition.

- The department also helps in the up gradation of technology.

- It is not wrong to refer to it as the Engineering department.

Role of the Maintenance Department

- Headed by the Chief Engineer.

- It comprises of a Civil Engineer, Mechanical Engineer, Electrical Engineer and a Stores Officer.

- Repair and construction of buildings and roads, plumbing, sanitation etc.

- Repair, maintenance and operation of boilers, gen sets, refrigeration etc.

- Repair, maintenance and installation of electrical equipment's.

- Maintenance and control of Inventory of spare parts and consumables.

- Equipment Replacement and purchase of new equipment's through proper tendering.

- Vendor development for supply of spare parts, equipment's and contract maintenance

- Maintenance of an engineering office for administrative work.

- Negotiation with employees union.

- Look after the recruitment , training, and proper placement of human power.

- Coordination with other departments of the hotel.

Organization of the maintenance department

Organization Chart of the Maintenance Dept.

Duties and Responsibilities of the Chief Engineer

- Chief Engineer has to ensure the smooth functioning of the Maintenance Department.

- The Chief Engineer is authorized to request various types of reports from his sub ordinates and analyze the same.

- To ensure smooth daily operation and guest appeal of the hotel.

- Organize and manage maintenance workers and participate in hiring, training and mentoring the staff.

- Supervise the maintenance work.

- Planning and scheduling of maintenance.

- Inviting tenders for contract maintenance.

- Budgeting of the maintenance department.

- Evaluation of the cumulative performance of the engineers.

- The Chief Engineer is answerable to the management in case of any negligence by the maintenance Department.

Civil Engineer

Areas of Concern- Building

- Renovation

- New Construction

- Sanitation

- STP – Sewage Treatment Plant

- WTP – Water Treatment Plant

- Drainage

- Water Works

- Roadways

Mechanical Engineer

Areas of Concern- Boiler

- Refrigeration

- AC Plant

- Generators

- Swimming Pool

- M/C (Machine ) Installation

- Fire Fighting

Electrical Engineer

- Areas of Concern

- Electric Motor

- Alternator Wiring

- Illumination

- Switch Gear

- Sensor and Detectors

- Communication

Store In charge

- Areas of Concern

- Inventory Control

- Spare parts Management

- Bin Card Stock Control

TYPES OF MAINTENANCE

Preventive Maintenance

- Preventive Maintenance is the maintenance action carried out on time based and condition based schedule.

- This type of maintenance is carried out before a fault is detected.

- It involves scheduling maintenance activities at predetermined time intervals.

- It also involves repairing or replacing damaged equipment's before obvious problems occur.

- It is further sub divided into a. Routine Maintenance b. Scheduled Maintenance c. Predictive Maintenance.

Routine Maintenance

In this type of maintenance, regular cleaning , lubrication of movable parts of machine and facilities is carried out.Scheduled Maintenance

- This category of maintenance is prepared and followed using experience and following manufacturer’s maintenance manual.

- Maintenance schedules of all machines are prepared , logbooks are maintained and minor repairs are routinely carried out before major breakdown occurs.

- It is a time consuming type of maintenance as it requires professional knowledge and skill.

- It aims at reducing machine stoppage due to sudden breakdown.

Predictive Maintenance

- This is a method in which the service life of important parts is predicted based on inspection or diagnosis, in order to use the parts to the limit of their service life.

- Machinery conditions are periodically monitored and this enables the maintenance crew to take timely action.

- It monitors the machinery periodically for excessive vibration, temperature, lubrication or other unhealthy trends.

- When the condition deteriorates to some predetermined unacceptable level, the equipment is shut down to repair or damaged components are replaced.

- This helps to prevent occurrence of a more costly failure.

Corrective Maintenance

- Also known as Running Maintenance

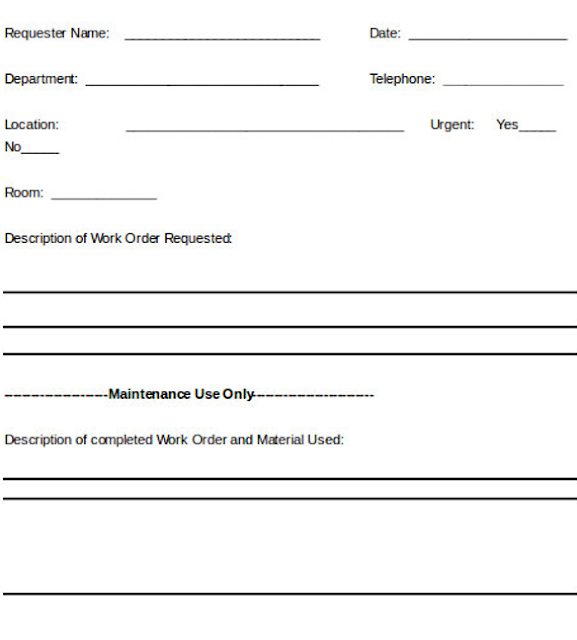

- This is a maintenance procedure where minor repair work is carried out on machines, initiated by a formal work order from the machine user department.

- The maintenance crew inspects the machine and does the repair work to run the machine in a short time.

WORK ORDER FORM

Breakdown Maintenance

- It involves performing maintenance activities after a breakdown or malfunction has occurred and then must be repair on an emergency or priority basis.

- Breakdown maintenance incudes repairs, replacement of parts or even overhaul to ensure that the machine is out back in operating condition.

- Breakdown maintenance is applicable to sophisticated machinery which proves very advantageous from cost point of view to allow them to run till they fail.

Emergency Maintenance

- It is carried out when a piece of equipment suddenly fails.

- Increases cost due to unplanned downtime of equipment's.

- May involve prolonged downtime if proper human power and components are not easily available.

- May increase costs associated with repair or replacement of equipment on urgent basis.

- Increases labour cost, especially if overtime is needed.

Preventive Maintenance v/s Breakdown Maintenance

Preventive Maintenance

- High Cost.

- Increases operational life of equipment.

- Results in an estimated 12 to 18 per cent cost saving as compared to breakdown maintenance .

- Maintenance activities that are not required are carried out.

Breakdown Maintenance

- Lower Cost.

- Allows the equipment to run up to the point of failure.

- May increase costs associated with repair or replacement of equipment on an urgent basis.

- No maintenance is carried out until a breakdown

Conclusion

- In the end it should be clear that maintenance of engineering and other facilities is one of the most critical activities in a hotel.

- It is both very complex and elaborate in the present era of highly developed technology in the hotel industry.

- It is not a revenue generating activity directly, such as F&B or accommodation, proper and regular maintenance definitely saves a lot of money by reducing down time of machines and equipments.

- It ensures guest satisfaction and high staff morale.

- Ultimately contributing immensely to the business of a hotel.